|

PLYWOOD

|

||||||||||||||||||||||||||||||||||

|

HOME | BIOLOGY | FILMS | GEOGRAPHY | HISTORY | INDEX | INVESTORS | MUSIC | SOLAR BOATS | SPORT |

||||||||||||||||||||||||||||||||||

|

Plywood was the first type of engineered wood to be invented. It is made from thin sheets of wood veneer, called plies or veneers, which are stacked together with the direction of each ply's grain differing from its neighbors by 90° (cross-banding). The plies are bonded under heat and pressure with strong adhesives, usually phenol formaldehyde resin, making plywood a type of composite material. A common reason for using plywood instead of plain wood is its resistance to shrinkage, twisting and warping.

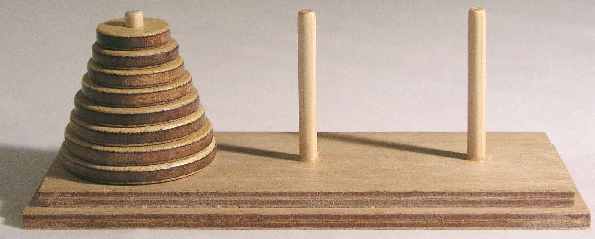

Plywood model - high quality wood veneer (light color) covering the lower quality inner wood (dark color)

Types of plywood

A vast number of varieties of plywood exist, tailored for all manner of conditions and uses. Softwood plywood is usually made either of Douglas fir or spruce, pine, and fir, and is typically used for construction and industrial purposes. Decorative plywood is usually faced with hardwood, including red oak, birch, maple, lauan (Philippine mahogany) and a large number of other hardwoods.

Plywood meant for indoor use generally uses the less expensive phenol formaldehyde glue (which has limited water resistance), while outdoor and marine grade plywood are designed to withstand rot and use a water resistant phenol-resorcinol glue to prevent delamination and retain strength in high humidity.

The most common varieties of softwood plywood comes in three, five or seven plies with dimensions of 1.2 m × 2.4 m (4 feet × 8 feet). Each ply is 1/8 inch. Roofing can use the thinnest 3/8-inch plywood. Floorboards are at least 5/8-inch depending on the distance between floor joists. Plywood is often tongue and grooved for flooring applications. Two of the edges will have "grooves" notched into them to fit with the adjacent "tongue" that protrudes from the next board.

High-strength plywood, known as airplane plywood is made from birch. It was used for several WWII fighter aircraft.

Airplane plywood was addapted for furniture by Alvar Aalto.

Plywood production

Plywood production requires a good log, called a peeler, generally straighter and larger in diameter than that required for processing by a sawmill. The log is peeled into sheets of veneer which are then cut to the desired dimensions, dried, patched and glued together to form the plywood panel. The panel can then be patched, resized, sanded or otherwise refinished, depending on the market it was intended to be sold in.

History

Plywood has been made for thousands of years; the earliest known occurrence of plywood was in ancient Egypt around 3500 BC when wooden articles were made from sawn veneers glued together crosswise. This was originally done due to a shortage of fine wood; thin sheets of high-quality wood were glued over a substrate of lower-quality wood for cosmetic effect, with the structural benefits arising only incidentally. This manner of inventing plywood has occurred repeatedly throughout history; for example, many of the great English furniture makers such as Sheridan used veneer as a raw material.

Modern plywood in which the veneer are cut on a rotary lathe from softwood logs is of relatively recent origin, invented by Immanuel Nobel (the father of the more-famous Alfred Nobel). The first such lathes were set up in the United States in the mid 19th century. Plywood has been one of the most ubiquitous building products for decades.

Compare to OSB (Oriented strand board) and MDF (Medium-density fibreboard).

References

LINKS:

http://www.forestsforever.org.uk

On October 14, 1994, members of the American Forest & Paper Association agreed to adhere to a set of forestry principles that would meet the needs of the present without compromising the ability of future generations to meet their own needs. These principles call for a land stewardship ethic which integrates the reforestation, nurturing, and harvesting of trees for useful products with the conservation of soil, air and water resources, wildlife and fish habitat, and forest aesthetics.

Forestry Pulp & Paper Wood Products Environment & Recycling

Belize - golden stream corridor preserve Brazil - Coastal Atlantic Forest Central America - Mesoamerican Biological Corridor (MBC) Chile - conservation of monkey puzzle forests Chile - remnant native forest in the mediterranean region China - Magnolia conservation (Proposed) Dominica - conservation of the national flower Ecuador - Awacachi Corridor Project Guatemala - threatened trees of Guatemala Liberia - re-starting nature conservation Madagascar - Vohibola Littoral Forest Mapping - threatened tree distributions Mauritius - threatened tree conservation Mexico - Oak & dry forest conservation Russia - Red Listing for trees SoundWood Instruments and Woods SoundWood Instruments and Woods - Pianos & Harpsichords SoundWood Instruments and Woods - Guitars, Banjos & Mandolins SoundWood Instruments and Woods- Harps SoundWood Instruments and Woods- Violins and Bows SoundWood Instruments and Woods- Woodwind SoundWood's Directory of Instrument Makers SoundWood's Directory of Wood Suppliers South Africa - Clanwilliam Cedar Sri Lanka - conservation profiles for Stemonoporus species St Helena - Millennium Gumwood Forest Tanzania - mpingo conservation project Uganda - sustainable drum production UK - public awareness of threatened trees UK - Wood waste and recycling project Vietnam - conifer conservation

A taste for adventure capitalists

Solar Cola - a healthier alternative

|

||||||||||||||||||||||||||||||||||

|